The 4th Guards Tank 'Kantemirovsky' Orders of Lenin and Red Banner Corps.

A brief history.

The 4th Guards Tank Corps antecedents were of an earlier wartime formation of the 17th Tank Corps. In late June 1942 the 17th Tank Corps took part during the Battle for Voronezh, being deployed west of the city and later in the Mid Don Operations 17-30th December 1942, where for distinguishing itself in combat it was to be renumbered as a Guards tank unit. Order No.1 of 3rd January 1943, of the NKO of the USSR authorised the creation of the 4th Guards Tank Corps, which was to be formed from brigades of the former 17th Tank Corps.

The following brigades made up the core of the new 4th Guards Tank Corps, namely 3rd Guards Motorised Rifle (former 31st), 12th Guards Tank (former 66th), 13th Guards Tank (former 67th) and the 14th Guards Tank (former 174th).During the course of the war the Corps composition also included separate regiments and battalions during different periods.

The Corps tactical identification insignia that was applied on the vehicles in the colour white and consisted of a pair of oak leaves with the Cyrillic letter Г (in Latin text the letter G) to denote Gvardiya (Guards)) superimposed over the left leaf. The respective units identification designation letter and or number were sometimes also incorporated centrally above the leaves and below the horizontal top of the letter Г.

Shortly after its formation on 3rd January 1943, the newly formed Corps had an early baptism of fire, for its part in the capture of Kantemirovka during the southern operations of the Voronezh Front, it was awarded the honorific title of 'Kantemirovsky', Order NKO No.42 on 27th January 1943 refers. In July and August 1943 the formation endured continuous combat on the Belgorod-Kharkov operations in the Kursk Salient. In April 1944, for courage and heroism shown during the liberation of cities on the right bank Ukraine, the Corps was awarded the Order of the Red Banner and seventeen regiments and separate battalions were awarded honorifics titles of: Shepetovsky, Zhitomirsky, Yampolsky, and Tarnopolsky. The Corps was also involved in the drive to the River Vistula in the autumn of 1944. During the subsequent Vistula-Oder Offensive the Corps was awarded the Order of Lenin for its part in the liberation of Krakow, Poland in January 1945.

There after in January 1945 the Corps specifically became a mobile army group for the 5th Guards Army and took part in the same areas of operations of the 13th Guards Rifle Division until the end of the war.

The 4th Guards Tank Corps was one of the first Soviet units to reach the River Elbe in April 1945. On the 28th April the Corps with elements of the 5th Guards Army were redirected from the Berlin offensive, south to Prague, Czechoslovakia. On route the Corps took part in the capture of the southern German city of Dresden, which had been severely damaged in February by Allied bombing. The Corps was also involved in the fighting for the suburbs of Prague during the very last hours of conflict of the war with the final German resistance in the city. During the course of the war the Corps was attached to the 27th, 60th Armies, 1st and 5th Guards(twice) and 59th Armies respectively as well as the STAVKA and various Front Reserves.

For the courage shown by soldiers and officers of the Corps, twenty three units received awards, the staff of the Corps was thanked officially by the Supreme commander in Chief eighteen times, thirty two of its members were awarded the title of Hero of the Soviet Union and more than twenty thousand received awards and medals, including five becoming Chevaliers of the Order of Glory.

On 14 June 1945 the 4th Guards Tank Corps was renamed the 4th Guards "Kantemirovskaya" Tank Division and on 13th September 1945 it was assigned to the armies of the Moscow Military District and was deployed to Naro-Forminsk in the Moscow Region.

The Corps 17th Tank Corps and 4th Guards Tank Corps respectively participated in the following operations of the Great Patriotic War:

The 4th Guards Tank Corps antecedents were of an earlier wartime formation of the 17th Tank Corps. In late June 1942 the 17th Tank Corps took part during the Battle for Voronezh, being deployed west of the city and later in the Mid Don Operations 17-30th December 1942, where for distinguishing itself in combat it was to be renumbered as a Guards tank unit. Order No.1 of 3rd January 1943, of the NKO of the USSR authorised the creation of the 4th Guards Tank Corps, which was to be formed from brigades of the former 17th Tank Corps.

The following brigades made up the core of the new 4th Guards Tank Corps, namely 3rd Guards Motorised Rifle (former 31st), 12th Guards Tank (former 66th), 13th Guards Tank (former 67th) and the 14th Guards Tank (former 174th).During the course of the war the Corps composition also included separate regiments and battalions during different periods.

The Corps tactical identification insignia that was applied on the vehicles in the colour white and consisted of a pair of oak leaves with the Cyrillic letter Г (in Latin text the letter G) to denote Gvardiya (Guards)) superimposed over the left leaf. The respective units identification designation letter and or number were sometimes also incorporated centrally above the leaves and below the horizontal top of the letter Г.

Shortly after its formation on 3rd January 1943, the newly formed Corps had an early baptism of fire, for its part in the capture of Kantemirovka during the southern operations of the Voronezh Front, it was awarded the honorific title of 'Kantemirovsky', Order NKO No.42 on 27th January 1943 refers. In July and August 1943 the formation endured continuous combat on the Belgorod-Kharkov operations in the Kursk Salient. In April 1944, for courage and heroism shown during the liberation of cities on the right bank Ukraine, the Corps was awarded the Order of the Red Banner and seventeen regiments and separate battalions were awarded honorifics titles of: Shepetovsky, Zhitomirsky, Yampolsky, and Tarnopolsky. The Corps was also involved in the drive to the River Vistula in the autumn of 1944. During the subsequent Vistula-Oder Offensive the Corps was awarded the Order of Lenin for its part in the liberation of Krakow, Poland in January 1945.

There after in January 1945 the Corps specifically became a mobile army group for the 5th Guards Army and took part in the same areas of operations of the 13th Guards Rifle Division until the end of the war.

The 4th Guards Tank Corps was one of the first Soviet units to reach the River Elbe in April 1945. On the 28th April the Corps with elements of the 5th Guards Army were redirected from the Berlin offensive, south to Prague, Czechoslovakia. On route the Corps took part in the capture of the southern German city of Dresden, which had been severely damaged in February by Allied bombing. The Corps was also involved in the fighting for the suburbs of Prague during the very last hours of conflict of the war with the final German resistance in the city. During the course of the war the Corps was attached to the 27th, 60th Armies, 1st and 5th Guards(twice) and 59th Armies respectively as well as the STAVKA and various Front Reserves.

For the courage shown by soldiers and officers of the Corps, twenty three units received awards, the staff of the Corps was thanked officially by the Supreme commander in Chief eighteen times, thirty two of its members were awarded the title of Hero of the Soviet Union and more than twenty thousand received awards and medals, including five becoming Chevaliers of the Order of Glory.

On 14 June 1945 the 4th Guards Tank Corps was renamed the 4th Guards "Kantemirovskaya" Tank Division and on 13th September 1945 it was assigned to the armies of the Moscow Military District and was deployed to Naro-Forminsk in the Moscow Region.

The Corps 17th Tank Corps and 4th Guards Tank Corps respectively participated in the following operations of the Great Patriotic War:

- Millerovo-Voroshilovgrad offensive operation (Operation Leap) [01/01/1943 - 22/02/1943]

- Kursk strategic defensive operation [05/07/1943 - 23/07/1943]

- Belogorod-Kharkov offensive operation (Operation "Rumyantsev") [03/08/1943 - 23/08/1943]

- Dnieper-Carpathian strategic offensive operation (Liberation of the Right-bank Ukraine) [24/12/1943 - 17/04/1944]

- Zhytomyr-Berdychiv front offensive operation [24/12/1943 - 14/01/1944]

- Rovno-Lutsk front offensive operation [27/01/1944 - 11/02/1944]

- Proskurovo-Chernivtsi front-line offensive operation [04/03/1944 - 17/04/1944]

- Lviv-Sandomierz strategic offensive operation [13/07/1944 - 29/08/1944]

- East Carpathian strategic offensive operation [08/09/1944 - 28/10/1944]

- Carpathian-Dukla front-line offensive operation

- Vistula-Oder strategic offensive operation [12/01/1945 - 03/02/1945]

- Sandomierz-Silesian Frontal Offensive Operation [12/01/1945 - 03/02/1945]

- Lower Silesian offensive operation [08/02/1945 - 24/02/1945]

- Berlin strategic offensive operation [16/04/1945 - 08/05/1945]

- Prague Strategic Offensive Operation [06/05/1945 - 11/05/1945]

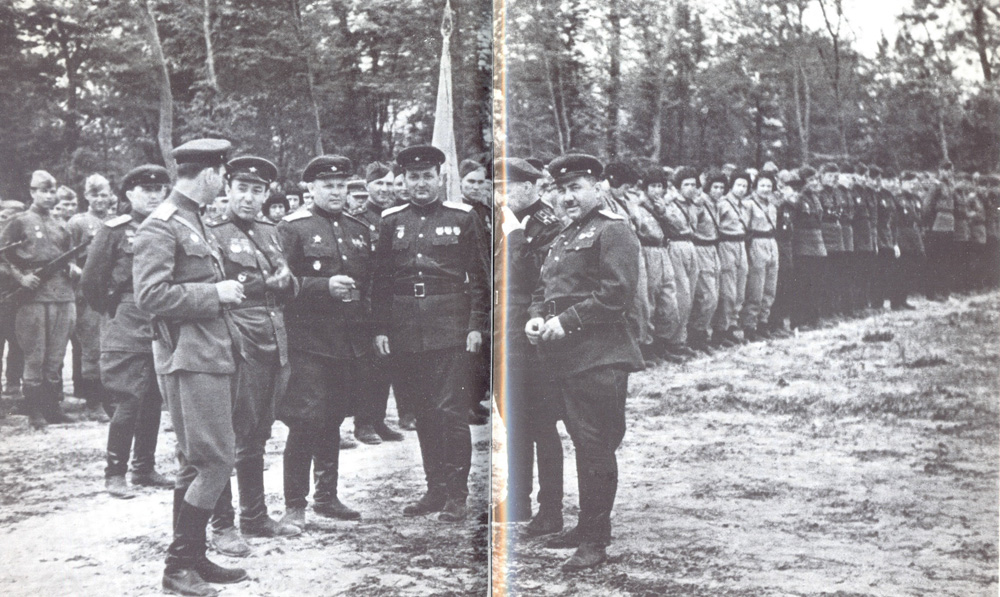

In the foreground is a group of commanders of the 4th Guards Tank Corps.(from left to right) Commander of the 12th Guards. Tank Brigade Colonel N. G. Dushak, Commander of the 14th Guards Tank Brigade Lieutenant Colonel AE Skirdanov, Commander of the 13th Guards Tank Brigade Colonel LI Baukov, deputy Corps Commander Colonel PK Shurenkov, Commander of the 3rd Guards Motorized Rifle Brigade Lieutenant Colonel MP Leonov and Chief of Staff of the Corps Colonel IA Nagaybakov, 1st May

1944, Terebovlya of the Tarnopol region.

1944, Terebovlya of the Tarnopol region.

The turret of the T34/85 is the late war 'composite' model with separate ventilation domes and bears the tactical insignia of the 4th Guards Tank Corps. The Corps as part of the 5th Guards Army took part in the Prague Strategic Operations in May 1945 and was involved in the street fighting in the suburbs of Prague for the liberation of the city. This image was taken in Moscow during the 7th November commemoration parade 1945

In February 2013 a T34/85 tank was incorporated into the unit under the auspices of the 13th Guards Tank Brigade of the 4th Guards Tank Corps.

The 13th Guards Tank 'Shepatovskaya' Orders of Red Banner,Suvorov and Kutusov Brigade.

The 13th Guards Tank 'Shepatovskaya' Orders of Red Banner,Suvorov and Kutusov Brigade.

T34/85.

This T34/85 is an example of what is sometimes referred to as "Production 45", the hull of which was produced from late 1944 onwards. However, the turret is a later variant, referred to as a "Production 46" , a late war 1945 example. The most distinctive identifying feature of both variants was the turret roof ventilation domes. The "Production 45" turret had twin domes situated behind the commanders cupola. The "Production 46" had separate 'mushroom' style domes, one situated in front and the other behind the commanders cupola.

Some variations, of which a few models only had a single ventilation dome behind the commanders cupola and other examples of late 1944 production models which also had separate 'mushroom' domes the same as the "Production 46". The most common model was the twin dome variant.

In September 2013 enquiries were made via the modern day Uralwagonzavod tank plant situated in Russia. From serial numbers on the vehicles hull, it has been established this particular tank was built at the same plant in December 1944 at Zavod (Factory) No. 183 at Nizhny Tagil in the Urals. However, the turret was made at Zavod (Factory) No. 112 "Krasnoe Sormovo" in Gorki (modern day Nizhny Novgorod, which is about 230miles due east from Moscow) It has the distinctive flat sided 'composite' turret, peculiar to Zavod 112 and was made in 1945 and is a late war variant. We have been informed via the Uralwagonzavod tank plant, that it is highly probable that this turret may be a replacement for the original one which was damaged in combat.

Factory 183 at Nizhny Tagil was the most productive maker of the T34 tank (15,014 T34/76 and 13,938 T34/85) of the seven factories that made the tank during the war. Factory 112 at Gorki became the second most productive maker of the T34 tank (6,396 T34/76 and 6,208 T34/85) Gorki produced T34/85 composite turrets are relatively uncommon, which makes this vehicle somewhat a rare wartime variant here in the UK.

This vehicle later saw service with the former Czechoslovakian Army and was imported to the UK from Slovakia in February 2013.

Some variations, of which a few models only had a single ventilation dome behind the commanders cupola and other examples of late 1944 production models which also had separate 'mushroom' domes the same as the "Production 46". The most common model was the twin dome variant.

In September 2013 enquiries were made via the modern day Uralwagonzavod tank plant situated in Russia. From serial numbers on the vehicles hull, it has been established this particular tank was built at the same plant in December 1944 at Zavod (Factory) No. 183 at Nizhny Tagil in the Urals. However, the turret was made at Zavod (Factory) No. 112 "Krasnoe Sormovo" in Gorki (modern day Nizhny Novgorod, which is about 230miles due east from Moscow) It has the distinctive flat sided 'composite' turret, peculiar to Zavod 112 and was made in 1945 and is a late war variant. We have been informed via the Uralwagonzavod tank plant, that it is highly probable that this turret may be a replacement for the original one which was damaged in combat.

Factory 183 at Nizhny Tagil was the most productive maker of the T34 tank (15,014 T34/76 and 13,938 T34/85) of the seven factories that made the tank during the war. Factory 112 at Gorki became the second most productive maker of the T34 tank (6,396 T34/76 and 6,208 T34/85) Gorki produced T34/85 composite turrets are relatively uncommon, which makes this vehicle somewhat a rare wartime variant here in the UK.

This vehicle later saw service with the former Czechoslovakian Army and was imported to the UK from Slovakia in February 2013.

Another view of the T34/85 showing the distinctive flat sided, sharp bottom edged and the 'rough' finish of the Zavod 112 produced turret. One of the distinctive 'mushroom' type ventilation domes can clearly been seen behind the commanders cupola.

The cable which was used by the crew to replace the tanks tracks in the field is shown in its retaining brackets

situated in front of the external fuel tank. These brackets are a post war addition to this particular vehicle. Internally there are some post war fitments from the vehicles service with the former Czech Army.

The cable which was used by the crew to replace the tanks tracks in the field is shown in its retaining brackets

situated in front of the external fuel tank. These brackets are a post war addition to this particular vehicle. Internally there are some post war fitments from the vehicles service with the former Czech Army.

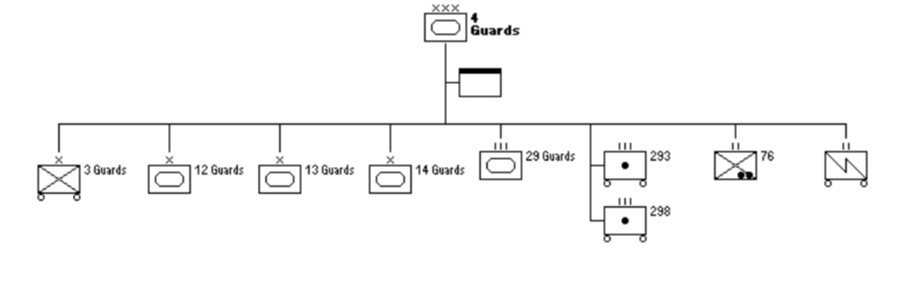

Composition of the 4th Guards Tank Corps from 9th July 1943 to 9th May 1945.

The 4th Guards Tank Corps formation from 9th July 1943 to 9th May 1945 included the below armed, supporting and service units. During the course of the war the Corps was attached to the 27th, 60th Armies, 1st and 5th Guards(twice) and 59th Armies respectively as well as the STAVKA and various Front Reserves.

From 1st January 1945, in the area of the Sandomierz bridgehead the 4th Guards Tank Corps came under the operational subordination of the 5th Guards Army, 1st Ukrainian Front. On 15th January it was briefly reassigned to the 59th Army, 1st Ukrainian Front until 29th January 29 1945, then it was again subordinated to the 5th Guards Army until the end of hostilities.

3rd Guards Motorised Infantry Brigade,12th,13th & 14th Guards Tank Brigades,29th Guards Heavy Tank Regiment,

293rd Motorised Artillery Regiment. 298th Motorised Artillery Regiment. 1451st Self-Propelled Artillery Regiment.

765th Anti-tank Artillery Regiment. 264th Separate Mortar Regiment.120th Guards Anti-aircraft Artillery Regiment.

76th Motorcycle Infantry Battalion. 22nd Armoured Reconnaissance Battalion (BA-64 & M3 scout vehicles).

413rd Signals Battalion. 106th Sapper Battalion. 226th Chemical Protection Company. 85th Field Tank Repair Company.

92nd Field Vehicle Repair Company. 17th Guards Motor Transport Company (fuel & lubricants supply).

3rd Aviation(Army) Liaison Flight(aviation liaison/communication). 24th Field Bakery Company.

1925th Field Pay Company of the State Bank. 2136th Military Postal Company.

Note: Tank, motorized and mechanized brigades had attached medical units comprising of approximately 32 personnel,which included surgical,nursing and orderly staff. Veterinary units were organized in accordance to the number of horse drawn field troops. A rifle division, for example, which has approximately 1,700 horses, had a veterinary aid station with only 11 officers and enlisted men. Tank, motorized, and mechanized units, which had very few horse drawn field troops or if at all any, so that their veterinary aid would have been substantially smaller.

From 1st January 1945, in the area of the Sandomierz bridgehead the 4th Guards Tank Corps came under the operational subordination of the 5th Guards Army, 1st Ukrainian Front. On 15th January it was briefly reassigned to the 59th Army, 1st Ukrainian Front until 29th January 29 1945, then it was again subordinated to the 5th Guards Army until the end of hostilities.

3rd Guards Motorised Infantry Brigade,12th,13th & 14th Guards Tank Brigades,29th Guards Heavy Tank Regiment,

293rd Motorised Artillery Regiment. 298th Motorised Artillery Regiment. 1451st Self-Propelled Artillery Regiment.

765th Anti-tank Artillery Regiment. 264th Separate Mortar Regiment.120th Guards Anti-aircraft Artillery Regiment.

76th Motorcycle Infantry Battalion. 22nd Armoured Reconnaissance Battalion (BA-64 & M3 scout vehicles).

413rd Signals Battalion. 106th Sapper Battalion. 226th Chemical Protection Company. 85th Field Tank Repair Company.

92nd Field Vehicle Repair Company. 17th Guards Motor Transport Company (fuel & lubricants supply).

3rd Aviation(Army) Liaison Flight(aviation liaison/communication). 24th Field Bakery Company.

1925th Field Pay Company of the State Bank. 2136th Military Postal Company.

Note: Tank, motorized and mechanized brigades had attached medical units comprising of approximately 32 personnel,which included surgical,nursing and orderly staff. Veterinary units were organized in accordance to the number of horse drawn field troops. A rifle division, for example, which has approximately 1,700 horses, had a veterinary aid station with only 11 officers and enlisted men. Tank, motorized, and mechanized units, which had very few horse drawn field troops or if at all any, so that their veterinary aid would have been substantially smaller.

T34/85 General information.

Produced in 1940, the T34 was the main battle tank of the Red Army during World War II or the Great Patriotic War as it is known in Russia and the former states of the Soviet Union. With its revolutionary sloping armour, excellent main armament, speed and maneuverability the T34/76 proved to be more than a match for any German tank on the battlefield during the early part of the war on the Eastern Front.

Inferior Soviet crew training and battlefield tactics did somewhat reduce the tanks effectiveness during this period. However, during the course of the war the Soviets did improve their training and tactics to match that of the Germans. Its design would set the bench mark for future post war tank development.

In response, the Germans in 1942 developed the Tiger and Panther tanks, which were better armed and had much improved armour than their previous tanks. Following the Battle of Kursk in July 1943, the Soviets realized the need to design a tank to combat the new German tanks. They opted for a redevelopment of the T34 against the new design T43 prototype, which took place during the latter months of 1943.

The existing hull turret ring was modified and strengthened to accept the new larger turret for the T34/85,which was designed at Factory 112 in Gorki by December 1943. Initially two separate main armaments were trialled, namely the 85mm D-5T and ZIS-S-53 guns. The ZIS-S- 53 85mm gun was later selected as the main armament and the T34/85 was born, making its combat debut in spring 1944.

Although the armament was still superior on the German tanks, the T34/85 proved a good weapon and the Soviets were able to produce them in such quantities to more than obviate their tank battlefield losses. The T34 medium tank remained in production until 1958 and was also built on licence after the war in Poland and Czechoslovakia. It has been in use in twenty six countries around the globe and it can still be found in armoured training and reserves units. It still remains in service with some armies in African and Asian states to this date.

Between June 1941 and May 1945 the Soviets produced the following: T34/76 ( 35,119 ) T34/85 ( 29,430) SU85 Self Propelled Gun ( 2,050) SU100 Tank Destroyer (1,675) both the self propelled gun and tank destroyer variants were built on the T34 chassis. Grand total built 68,274.

Specifications.

The hull was divided into four compartments: Driving, Fighting, Engine and the Transmission.

Crew Five: Commander, Driver/mechanic, Gunner, Loader and Hull machine gunner/(radio operator-pre March 1944 T34's)

Length 26' 6" / 8.09 metres.

Width 9' 9" / 2.97 metres.

Height 9’0" / 2.75 metres.

Weight 32 Imp.tons / 32,580 Kg. (Combat ready weight)

Armour 90 mm (turret front); 75 mm (turret rest) 47 mm (hull glacis, rear); 60 mm (hull sides)

Speed Road 34 mph / 54.5 Km/h, Off road 16 mph / 25.5 Km/h.

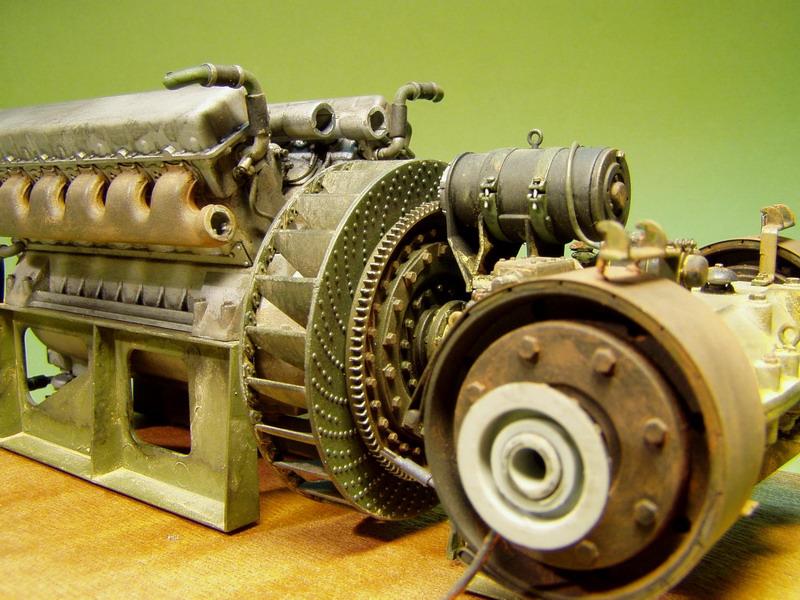

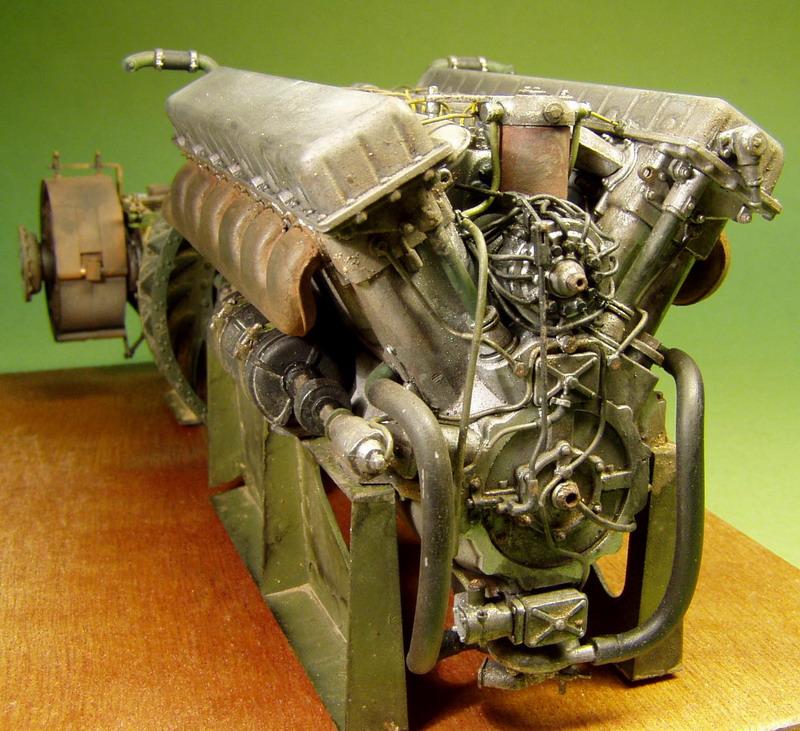

Engine The T-34-85 is powered by a V-2-34 diesel engine. It is a 12 cylinder, 38.8 litre, four-stroke, liquid-cooled engine that develops 373 kW (500 horsepower) at 1,800 RPM and 222 kg-m of torque at 1,100 - 1,200 RPM. The engine is governed at 2,100 RPM and weighs 900kg. Drive is via a 6 speed crash gearbox using normal clutch, throttle and brake controls with two steering levers.

Note: From October of 1941 to April of 1942 inclusive, when tank factories had to be evacuated further east, tank production decreased significantly and the shortfall had to be made up with by producing the simpler if less effective M-17T petrol/gasoline engine for the T34.

During this period some 943 T-34 tanks were produced and delivered with M-17T and M-17F petrol/gasoline engines which was vital to the Soviet war effort. The M-17T V-12 four stroke petrol/gasoline engine had derived from M-17F aircraft engine and was adapted for use in tanks. The maximum power of the M-17F was 715 hp, but was reduced to 500 hp. Both the M-17T and M-17F ran on B-70 aircraft petrol/gasoline. Before the war, M-17T engines were produced and installed in BT-7 tanks. The M-17L engine variant was also used on T-28 and T-35 tanks, which had a higher output of 650 hp and an air starter system.

The M-17 series engines were never a long term alternative to the V-2-34 diesel engine, which was more effective because of its reduced fuel consumption and greater cruising range, more stable temperature range during operation,simplicity of service and reduced fire risk.

Power-to-weight ratio 14.2hp/t.

Transmission Dry multi plate clutch, mechanical gearbox, One stage side drives with side clutches and strap brakes, with 5 forward and 1 reverse gears.

Fuel capacity 545 litres internal, 270 litres external. Total 815 litres. Range 250–300 km/150 miles depending on terrain.

Fuel consumption 1.5 gallon per mile/6.8 litres per 1.6 km. (on the road)

Armament Either D-5T-85 or ZIS-S-53 85 mm main gun & two 7.62 mm machine guns.

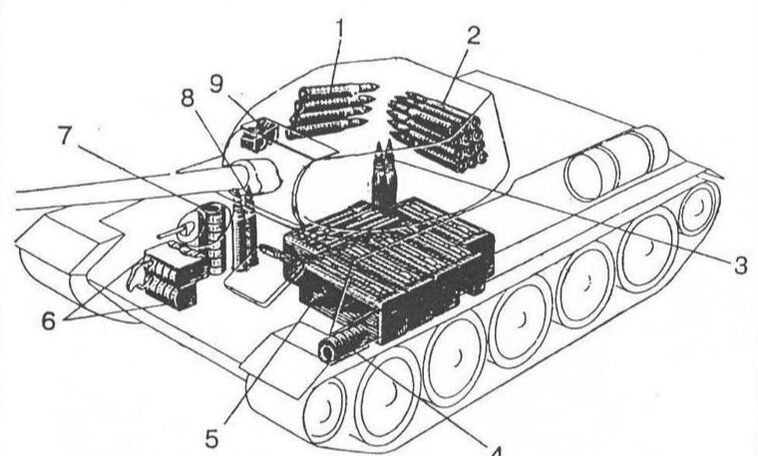

Ammunition 55 main gun shells , 1,827 7.62 x 54R machine gun rounds,contained in 31 drum magazines.

The turret can be rotated manually or powered electrically, under power it will rotate through 360 degrees in less than 15 seconds. The main gun can be elevated from -5 to +25 degrees from the horizontal, and will fire at a rate of 10 rounds per minute whilst stationary and 4 rounds per minute whilst on the move. Maximum range of main armament is 12.9 km (that’s 8 miles!)

The tank is capable of climbing a gradient of 60 degrees; it can cross a ditch 8 feet wide (2.44 mtr) and wade water obstacles up to 4’ foot 4 inches deep (1.32 mtr).

Main armament parameters.

D-5T. ZIS-S-53.

Calibre (mm). 85 85

Bore length (calibers). 51.6 54.6

Weight recoil elements (kg). 980 905

Trunnion weight (kg) 1500 1150

Max recoil (mtr) 0.33 0.33

Elevation (degrees) -5 +22 -5 +25

Practical rate of fire (rounds per min.) 5 - 8 6 - 10

Note:

The term calibres is used to determine the length of the gun tube. It is calculated by multiples of the bore diameter into the gun tube length i.e, bore of 85 mm and in the case of the ZIS-S-53 gun the calibres is 54.6 times the size of the bore diameter, nearly five and a half metres.

Main armament ammunition.

Each tank had a basic load of 55 rounds, but could carry up to 60 rounds. The number of each type round carried are shown in brackets.

UO-365K Fragmentation Round. (36)

UBR-365 Armour-Piercing Round. (14)

UBR-365P Sub-Calibre Armour-Piercing Projectile. (5)

Ammunition details.

Round Projectile Type. Fuse. Weight Description.

index. index. kg.

UO-365K O-365K Fragmentation KTM-1 9.54 Steel case.

UBR-365 BR-365 Armour piercing MD-5 or 9.2 Steel case: tracer.

(APHE) MD-7

UBR-365K BR-365K Armour piercing MD-8 9.2 " " "

(APBC)

UBR-365P BR-365P Sub calibre n/a 4.99 Introduced Feb 44.

Inferior Soviet crew training and battlefield tactics did somewhat reduce the tanks effectiveness during this period. However, during the course of the war the Soviets did improve their training and tactics to match that of the Germans. Its design would set the bench mark for future post war tank development.

In response, the Germans in 1942 developed the Tiger and Panther tanks, which were better armed and had much improved armour than their previous tanks. Following the Battle of Kursk in July 1943, the Soviets realized the need to design a tank to combat the new German tanks. They opted for a redevelopment of the T34 against the new design T43 prototype, which took place during the latter months of 1943.

The existing hull turret ring was modified and strengthened to accept the new larger turret for the T34/85,which was designed at Factory 112 in Gorki by December 1943. Initially two separate main armaments were trialled, namely the 85mm D-5T and ZIS-S-53 guns. The ZIS-S- 53 85mm gun was later selected as the main armament and the T34/85 was born, making its combat debut in spring 1944.

Although the armament was still superior on the German tanks, the T34/85 proved a good weapon and the Soviets were able to produce them in such quantities to more than obviate their tank battlefield losses. The T34 medium tank remained in production until 1958 and was also built on licence after the war in Poland and Czechoslovakia. It has been in use in twenty six countries around the globe and it can still be found in armoured training and reserves units. It still remains in service with some armies in African and Asian states to this date.

Between June 1941 and May 1945 the Soviets produced the following: T34/76 ( 35,119 ) T34/85 ( 29,430) SU85 Self Propelled Gun ( 2,050) SU100 Tank Destroyer (1,675) both the self propelled gun and tank destroyer variants were built on the T34 chassis. Grand total built 68,274.

Specifications.

The hull was divided into four compartments: Driving, Fighting, Engine and the Transmission.

Crew Five: Commander, Driver/mechanic, Gunner, Loader and Hull machine gunner/(radio operator-pre March 1944 T34's)

Length 26' 6" / 8.09 metres.

Width 9' 9" / 2.97 metres.

Height 9’0" / 2.75 metres.

Weight 32 Imp.tons / 32,580 Kg. (Combat ready weight)

Armour 90 mm (turret front); 75 mm (turret rest) 47 mm (hull glacis, rear); 60 mm (hull sides)

Speed Road 34 mph / 54.5 Km/h, Off road 16 mph / 25.5 Km/h.

Engine The T-34-85 is powered by a V-2-34 diesel engine. It is a 12 cylinder, 38.8 litre, four-stroke, liquid-cooled engine that develops 373 kW (500 horsepower) at 1,800 RPM and 222 kg-m of torque at 1,100 - 1,200 RPM. The engine is governed at 2,100 RPM and weighs 900kg. Drive is via a 6 speed crash gearbox using normal clutch, throttle and brake controls with two steering levers.

Note: From October of 1941 to April of 1942 inclusive, when tank factories had to be evacuated further east, tank production decreased significantly and the shortfall had to be made up with by producing the simpler if less effective M-17T petrol/gasoline engine for the T34.

During this period some 943 T-34 tanks were produced and delivered with M-17T and M-17F petrol/gasoline engines which was vital to the Soviet war effort. The M-17T V-12 four stroke petrol/gasoline engine had derived from M-17F aircraft engine and was adapted for use in tanks. The maximum power of the M-17F was 715 hp, but was reduced to 500 hp. Both the M-17T and M-17F ran on B-70 aircraft petrol/gasoline. Before the war, M-17T engines were produced and installed in BT-7 tanks. The M-17L engine variant was also used on T-28 and T-35 tanks, which had a higher output of 650 hp and an air starter system.

The M-17 series engines were never a long term alternative to the V-2-34 diesel engine, which was more effective because of its reduced fuel consumption and greater cruising range, more stable temperature range during operation,simplicity of service and reduced fire risk.

Power-to-weight ratio 14.2hp/t.

Transmission Dry multi plate clutch, mechanical gearbox, One stage side drives with side clutches and strap brakes, with 5 forward and 1 reverse gears.

Fuel capacity 545 litres internal, 270 litres external. Total 815 litres. Range 250–300 km/150 miles depending on terrain.

Fuel consumption 1.5 gallon per mile/6.8 litres per 1.6 km. (on the road)

Armament Either D-5T-85 or ZIS-S-53 85 mm main gun & two 7.62 mm machine guns.

Ammunition 55 main gun shells , 1,827 7.62 x 54R machine gun rounds,contained in 31 drum magazines.

The turret can be rotated manually or powered electrically, under power it will rotate through 360 degrees in less than 15 seconds. The main gun can be elevated from -5 to +25 degrees from the horizontal, and will fire at a rate of 10 rounds per minute whilst stationary and 4 rounds per minute whilst on the move. Maximum range of main armament is 12.9 km (that’s 8 miles!)

The tank is capable of climbing a gradient of 60 degrees; it can cross a ditch 8 feet wide (2.44 mtr) and wade water obstacles up to 4’ foot 4 inches deep (1.32 mtr).

Main armament parameters.

D-5T. ZIS-S-53.

Calibre (mm). 85 85

Bore length (calibers). 51.6 54.6

Weight recoil elements (kg). 980 905

Trunnion weight (kg) 1500 1150

Max recoil (mtr) 0.33 0.33

Elevation (degrees) -5 +22 -5 +25

Practical rate of fire (rounds per min.) 5 - 8 6 - 10

Note:

The term calibres is used to determine the length of the gun tube. It is calculated by multiples of the bore diameter into the gun tube length i.e, bore of 85 mm and in the case of the ZIS-S-53 gun the calibres is 54.6 times the size of the bore diameter, nearly five and a half metres.

Main armament ammunition.

Each tank had a basic load of 55 rounds, but could carry up to 60 rounds. The number of each type round carried are shown in brackets.

UO-365K Fragmentation Round. (36)

UBR-365 Armour-Piercing Round. (14)

UBR-365P Sub-Calibre Armour-Piercing Projectile. (5)

Ammunition details.

Round Projectile Type. Fuse. Weight Description.

index. index. kg.

UO-365K O-365K Fragmentation KTM-1 9.54 Steel case.

UBR-365 BR-365 Armour piercing MD-5 or 9.2 Steel case: tracer.

(APHE) MD-7

UBR-365K BR-365K Armour piercing MD-8 9.2 " " "

(APBC)

UBR-365P BR-365P Sub calibre n/a 4.99 Introduced Feb 44.

The commander and the gun aimer were situated on the left of the breach. The gunners TSh-16 optical sight is clearly visible above the manual cranks for gun elevation(green) and turret traverse(white).The electric traverse motor was activated by locating and locking the crank handle in the recess shown on the left side of the crank assembly, Pushing the handle up or down, the turret could be traversed in either direction. The loader was positioned on the right of the breach. At top right and top left, painted green are the MK-4 observation periscopes. Note: the magazines for the co axial machine gun on the right turret wall. The T34 unlike many tanks did not have an internal turret cage. The commander had a fold down seat attached to the turret ring and the gunners seat was attached to the gun frame assembly. The loader had a suspended saddle type seat attached to the turret ring, which was folded out of the way in combat, the loader having to stand on the ammo bins on the hull floor.

View taken behind the drivers seat. The hull gunner is situated on the drivers right. Also seen are the racks for up to 60 round magazines for the DT 7.62 machine gun. A rack holding another 5 magazines was situated on the left of the drivers seat. Note: behind the seats are the ammo bins for the main armament, 85mm gun, situated on the floor of the turret fighting compartment. Ammo racks for the main gun were also situated in the rear turret bustle and sides of the turret interior and also next to the hull gunners seat, which in total held 20 rounds. The hull gunner also operated the vehicle radio, until the radio was moved into the turret on vehicles manufactured after March 1944.Just visible on the floor in front of the gunners seat is the auxiliary armoured escape hatch

A view of the interior looking through the open drivers hatch. The gun aimers seat, painted white is on the right and below that is the pedal operated trigger mechanism for the main gun. On the left next to the first aid box and thermos flask is the stowed loaders saddle seat.

Below is the storage bins for F1 grenades. Up to a total of 10 pouches, each containing 3 grenades could be stored in the bins. On the floor can be seen one of the bogie wheel suspension spindles, which would otherwise be concealed under under the main armament ammo bins. Note: the bulkhead covers have been removed to expose the engine compartment interior and to allow access to the fuze box and lubrication points etc.Top centre, just visible, painted dark grey is one of the two crank handles used to operate the engine deck louvres from inside the fighting compartment of the vehicle.

Exterior views of the T34/85.

A view of the front and offside of the vehicle.

On the front can be seen the towing cable and some spare links of track. Spare track links were stowed on the front and turret sides and also to act as additional armour protection.

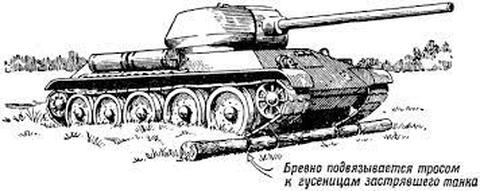

The distinctive sharp bottom edge and rough finish of the Zavod 112 produced turret is clearly visible, as are the separate 'mushroom' ventilation roof domes of this late war produced vehicle. The round protrusions on both turret sides are pistol ports. On late war turrets there was also a viewing slit on the right side only, above the pistol port. Early models had viewing slits on both sides. This particular variant has no viewing slits on the turret sides at all. On the offside is a breaching log, used when the vehicle had to negotiate obstacles such as wide ditches. Two of the three external fuel tanks can also be seen. A third tank was on the rear nearside of the hull. This vehicle is not fitted with the front track fenders, which were often removed when they became damaged Image taken at the War & Peace Revival Show, Kent 2013.

On the front can be seen the towing cable and some spare links of track. Spare track links were stowed on the front and turret sides and also to act as additional armour protection.

The distinctive sharp bottom edge and rough finish of the Zavod 112 produced turret is clearly visible, as are the separate 'mushroom' ventilation roof domes of this late war produced vehicle. The round protrusions on both turret sides are pistol ports. On late war turrets there was also a viewing slit on the right side only, above the pistol port. Early models had viewing slits on both sides. This particular variant has no viewing slits on the turret sides at all. On the offside is a breaching log, used when the vehicle had to negotiate obstacles such as wide ditches. Two of the three external fuel tanks can also be seen. A third tank was on the rear nearside of the hull. This vehicle is not fitted with the front track fenders, which were often removed when they became damaged Image taken at the War & Peace Revival Show, Kent 2013.

A view of the nearside of the vehicle.

On the nearside, near the front is the tool box and at the rear the third external fuel tank. A tarpaulin and shovel are also tied to the hull side. Above the tarpaulin one of the engine deck side louvres can be seen. These can be operated from within the fighting compartment by levers, to control engine heat dissipation. The grab handles for the 'tank riders' are also visible on both the turret and hull sides. The layout of the wheel configuration can be clearly seen. The rear wheel is the drive sprocket with five road wheels and at the front is the idler wheel. Note: the larger spacing between the 2nd and 3rd road wheels. The vehicle is fitted with the "full spider" type wheels, which each has 12 full-radius reinforcing ribs with 12 large and small lightening holes, with solid rubber tyres and no tyre side perforations. The full-spider wheel" entered production in late 1943, although it is more common to see this type of wheel installed on very late-war and post-war vehicles. The track guide 'horns' which are visible (on every other track link section) which served to mesh with the rear drive sprocket wheels and also to keep the track in place on the front idler and road wheels.

A rear view of the vehicle.

A rear view of the tank showing the exhaust and the round hatch for servicing the transmission. On earlier model T34's the hatch was square in shape. The rear armoured plate is hinged to facilitate major overhaul, such as engine or transmission removal. The bulges either side of the rear towing hooks are the casings for the final drive to the rear drive sprockets. Note: the track pin heads protruding on the inner side of the track. The pins are not secured, as each pin strikes a 'keeper' on either side of the rear hull, tapping the pin back into place as the track rotates, which gives the T34 its distinctive sound when in motion. Each track has 74 steel links and 148 pins. The exhaust shrouds are the wartime type i.e. with straight edges, whereas post war shrouds have 'scalloped' edges around the fixing bolts. The fairing situated on the rear nearside of the vehicle, just below the external fuel tank, houses the infantry call button. This was used by ensuing infantry or tank borne troops to alert the attention of the tank crew. This version is a post war addition when the vehicle was in service with the Czech Army.

A rear view of the tank showing the exhaust and the round hatch for servicing the transmission. On earlier model T34's the hatch was square in shape. The rear armoured plate is hinged to facilitate major overhaul, such as engine or transmission removal. The bulges either side of the rear towing hooks are the casings for the final drive to the rear drive sprockets. Note: the track pin heads protruding on the inner side of the track. The pins are not secured, as each pin strikes a 'keeper' on either side of the rear hull, tapping the pin back into place as the track rotates, which gives the T34 its distinctive sound when in motion. Each track has 74 steel links and 148 pins. The exhaust shrouds are the wartime type i.e. with straight edges, whereas post war shrouds have 'scalloped' edges around the fixing bolts. The fairing situated on the rear nearside of the vehicle, just below the external fuel tank, houses the infantry call button. This was used by ensuing infantry or tank borne troops to alert the attention of the tank crew. This version is a post war addition when the vehicle was in service with the Czech Army.

T34/85. A view of the front turret and main gun mantle. The crude casting and welding of wartime manufacturing is evident. Visible on the front hull glasis just below the front turret ring, is a crudely welded length of metal strengthening. Similar strengthening was also added to each side of the hull below the turret ring. These were expedient developmental measures in the T34's production to adapt the vehicles hull to accept the new larger turret and 85 mm gun in late 1944.

T34/85. A view of the offside, showing the breaching log, metal snow/ice cleats, tool box and external fuel tank. The log was used to cross obstacles and wide ditches. The cleats were bolted to the tracks at spaced intervals, to enable the tank to be driven on extreme iced surfaces. The cut branches and sticks shown, were often carried so that crews could erect a basic shelter in conjunction with a tarpaulin in inclement weather conditions. Just above and partially concealed by the sticks is one of the hull side turret ring metal strengthening weldings.

Image from a period manual showing the how the log was to be attached to the tracks.

Image from a period manual showing the how the log was to be attached to the tracks.

Why was it common to see Soviet tanks carrying a log strapped to its side?

During the campaign on the Eastern Front vehicles had to contend with vast areas of swamp,marsh and during the spring and autumn rain seasons extreme mud, often resulting in being immobilized due to loss of traction, particularly heavier armoured tracked vehicles.

The log was attached to the the front tracks between the front idler and front road wheels with metal cables. The tank was slowly driven forward over the log, which compressed it into the soft surface and provided traction and propelled the vehicle forward as it passed over the log until it reached the rear drive sprocket. As necessary, the process may have had to be repeated to clear the obstacle. The same method was used in the case where the hull bottom had become beached upon a solid object i.e. large rock, debris or tree stump etc and the tracks traction could not be sufficiently transferred to the ground surface. As the log passed under the tank it engaged the object, usually sufficient to force the hull free off the object. Also, a log or number of logs could be used to breach wide ditches and trenches. The carrying of logs on AFVs is still practiced today in armies of Russia, the former states of USSR, Middle East and China.

During the campaign on the Eastern Front vehicles had to contend with vast areas of swamp,marsh and during the spring and autumn rain seasons extreme mud, often resulting in being immobilized due to loss of traction, particularly heavier armoured tracked vehicles.

The log was attached to the the front tracks between the front idler and front road wheels with metal cables. The tank was slowly driven forward over the log, which compressed it into the soft surface and provided traction and propelled the vehicle forward as it passed over the log until it reached the rear drive sprocket. As necessary, the process may have had to be repeated to clear the obstacle. The same method was used in the case where the hull bottom had become beached upon a solid object i.e. large rock, debris or tree stump etc and the tracks traction could not be sufficiently transferred to the ground surface. As the log passed under the tank it engaged the object, usually sufficient to force the hull free off the object. Also, a log or number of logs could be used to breach wide ditches and trenches. The carrying of logs on AFVs is still practiced today in armies of Russia, the former states of USSR, Middle East and China.

T34/85. A view of the rear offside, showing the armour plating of the engine compartment. Equipment was often stored and lashed to the exterior of the vehicle. However, in combat such equipment, would be stored on the sides, so that it would not impede turret traversing. The green canvas bag seen below the external fuel tank, is a fire extinguisher, a modern H&S requirement for public events.

Article from Russian magazine " Defenders of the Fatherland", September 2013 issue.

Below is an article which was in the Russian military magazine " Defenders of the Fatherland" of September 2013 issue. It also appeared at an exhibition at the Uralwagonzavod tank plant . It is a feature about the T34 tank in use here in the UK with the 13th Guards. The article refers to exchange visits between our groups to Moscow and the War & Peace Show in Kent. A brief translation of the article is reproduced below.

This piece was written by retired Russian Army Colonel Sergey Larionov, whose group ‘Club Division’ patriotic military club in Moscow are honorary members of the 13th Guards Rifle Division here in the UK. Sergey wrote the piece for an exhibition, taking place in Nizhny Tagil, Russia, at the Uralwagonzavod tank factory in September 2013. In 1941 the Uralwagonzavod Zavod 183 (Factory 183) became the largest tank factory in the world and over the course of the “Great Patriotic War” was the largest producer of T-34′s.

Sergey describes how on his first visit to the War & Peace show he was surprised to find re enactors portraying familiar Soviet military units and even more surprised by the wide variety, quality and condition of the Soviet military equipment and weapons on display.

He also says he was impressed and touched by the knowledge shown by members of the 13th Guards Rifle Division. The article also talks about the T-34 tank, how it came to be used by the 13th Guards in the UK. The text is accompanied by photographs from the War & Peace Show and Victory Day commemorations in Moscow 2012 which were attended by members of the 13th Guards unit. The piece goes on to explain that records held at the Uralwagonzavod revealed the T-34 was made at the Zavod 183 plant in December of 1944, but how the turret was made at another plant, Zavod 112 at Krasnoe Sormavo, Gorki, now known as Nizhny Novgorod, near Moscow in 1945, which suggest the tank was at some point combat damaged and had its turret replaced.

As a result of this British Soviet exchange, members of the 13th Guards Rifle Division “Poltavaskaya” have been invited by Uralwagonzavod plant management to the works as their guests of honour for a future exhibition.

T34. Private land driving.

The below set of images were taken late December 2016, where there was an opportunity to drive the T34 on private land for two days, both on open farmland and in a wooded area. Members were joined by family and friends.

GAZ 67B General purpose four wheel drive light utility vehicle, "Chapaev".

GAZ 67B GENERAL PURPOSE LIGHT UTILITY VEHICLE, "CHAPAEV".

This Soviet manufactured vehicle was influenced by the American built Bantam and Willys Jeeps, which were supplied to the Soviet Union under the wartime Lend Lease agreement.

The GAZ 67 was a further development of the earlier Soviet designed GAZ 64 vehicle of 1941-42, which included an increased track size, new carburettor, thermostat, larger fuel tank, stronger chassis and modification details to the vehicle body. It was made at the Gorki Automobile Factory (Gorkovsky Avtomobilny Zavod) in Nizhny Novgorod.

The factory was heavily damaged by German bombing in June 1943, therefore production of the vehicle did not commence until September 1943. After a short production run of only 718 GAZ 67 vehicles, in January 1944 some minor mechanical improvements were made and this variant is known as the GAZ 67B.

The GAZ 67B was often used to tow artillery pieces and was capable of towing either the 45mm Model 37/42 or a 57mm ZIS 2 Model 43 anti tank guns or a ZIS 3 76mm Divisional gun, although the latter two guns far exceeded the vehicles official towing capacity. It was also used with the 7.62mm Maxim or SG-43 Guronov heavy machine gun mounted in the rear of the vehicle.

An armoured car version was based on the GAZ 64/67B chassis and was known as the BA 64.

The GAZ 67B was in production between 1943-1953 with some modifications and 92,843 were made altogether.

The example pictured was made in 1945 and has been fully restored to a museum standard and was imported to the UK in September 2013 from Slovakia.

Specifications.

LAY OUT: Front engine four wheel drive vehicle.

ENGINE: In line 4 cylinder water cooled petrol. Displacement: 3,285 litres. Power: 50 hp @2800 rpm (54 hp for GAZ 67B). Max speed: 90/ 56 mph. Fuel tank capacity: 70 litres/15.5 gallons. Fuel consumption: 15 ltr- 100 km/ 3.3 gall - 62 miles.

TRANSMISSION: Unsynchronised manual mechanical gearbox. 4 forward gears, one reverse gear and one reduction gear for deactivating the front wheel drive.

DIMENSIONS: Wheelbase: 2,100 mm/82.7 in.

Length: 3,345 mm/131.7 in.

Width: 1,685 mm/66.3 in.

Height: 1,700 mm/66.9 in.

Kerb weight: 1,320 kg/2,910 lbs.

This Soviet manufactured vehicle was influenced by the American built Bantam and Willys Jeeps, which were supplied to the Soviet Union under the wartime Lend Lease agreement.

The GAZ 67 was a further development of the earlier Soviet designed GAZ 64 vehicle of 1941-42, which included an increased track size, new carburettor, thermostat, larger fuel tank, stronger chassis and modification details to the vehicle body. It was made at the Gorki Automobile Factory (Gorkovsky Avtomobilny Zavod) in Nizhny Novgorod.

The factory was heavily damaged by German bombing in June 1943, therefore production of the vehicle did not commence until September 1943. After a short production run of only 718 GAZ 67 vehicles, in January 1944 some minor mechanical improvements were made and this variant is known as the GAZ 67B.

The GAZ 67B was often used to tow artillery pieces and was capable of towing either the 45mm Model 37/42 or a 57mm ZIS 2 Model 43 anti tank guns or a ZIS 3 76mm Divisional gun, although the latter two guns far exceeded the vehicles official towing capacity. It was also used with the 7.62mm Maxim or SG-43 Guronov heavy machine gun mounted in the rear of the vehicle.

An armoured car version was based on the GAZ 64/67B chassis and was known as the BA 64.

The GAZ 67B was in production between 1943-1953 with some modifications and 92,843 were made altogether.

The example pictured was made in 1945 and has been fully restored to a museum standard and was imported to the UK in September 2013 from Slovakia.

Specifications.

LAY OUT: Front engine four wheel drive vehicle.

ENGINE: In line 4 cylinder water cooled petrol. Displacement: 3,285 litres. Power: 50 hp @2800 rpm (54 hp for GAZ 67B). Max speed: 90/ 56 mph. Fuel tank capacity: 70 litres/15.5 gallons. Fuel consumption: 15 ltr- 100 km/ 3.3 gall - 62 miles.

TRANSMISSION: Unsynchronised manual mechanical gearbox. 4 forward gears, one reverse gear and one reduction gear for deactivating the front wheel drive.

DIMENSIONS: Wheelbase: 2,100 mm/82.7 in.

Length: 3,345 mm/131.7 in.

Width: 1,685 mm/66.3 in.

Height: 1,700 mm/66.9 in.

Kerb weight: 1,320 kg/2,910 lbs.

GAZ-AA, 1½-ton 4x2, Cargo Truck.

The origin of the GAZ AA truck is derived from the FORD AA truck, which was originally designed in 1926. Ford licensed the manufacture of the vehicle to several countries, including the Soviet Union in 1930, where it was generally produced between 1932- 1950. It was manufactured at the Gorki Automobile Factory (Gorkovsky Avtomobilny Zavod) in Nizhny Novgorod until 1947 and thereafter at the UAZ (Ulyanovsk Automobile Plant) in Ulyanovsk, between 1947-1950. In total some 985,000 vehicles were produced.

The first GAZ-AA's were made according to specifications of the original Ford, however Soviet designers found it necessary to make some changes including strengthening the clutch, steering gear, install an air filter, other components and simplification of the model. Incidentally, the GAZ-AA had no fuel pump. The tank was located in front of the wind screen above the carburettor and fuel was fed into it by gravity. The vehicle also shared many components with the GAZ 67 light utility vehicle, including the engine. The vehicle was produced in many guises for civil use i.e. medical, fire, police, buses as well as commercial transport etc.

It was also adopted by the Red Army and 151,000 were in use at the start of the Great Patriotic War. The vehicle delivered the base for countless variations, for troop and cargo transport, ambulances, buses, command, signal, fuel bowsers, artillery towing, mobile workshop, vehicle mounted anti-aircraft gun and quadruple machine gun use, as well as the 3-axle GAZ-AAA and the GAZ-60 halftrack variants.

The term GAZ MM was the designation for wartime vehicles produced from early 1942 on wards. It incorporated the strengthened engine introduced in 1938, increasing output from 42 to 50 hp. Modifications varied, including a canvas or leatherette roof, plain welded steel fenders replacing the curved pressed ones, no front brakes, no front bumper bar and sometimes no doors, and only one headlight From mid-1942 trucks were also produced with wooden doors with sliding part windows. In 1944 the hinged drop side panels were abolished leaving the tailgate hinged only.

It was nicknamed the " Polutorka", which referred to the vehicles payload capacity of one and a half tons.(Transliteration in Russian, "poltora" means one and a half).

The example pictured was made in 1940 and is fitted with the pre 1941 cab with pressed steel doors. Apparently it went back to the factory at some point after being damaged in the field to have a plate welded on the chassis (combat damage?).

At the same time the curved pressed steel fenders may have also been changed for the flat welded steel fenders.

It was imported into the UK in August 2015 from Slovakia.

Specifications.

LAY OUT: Front engine rear wheel drive vehicle.

ENGINE: GAZ-M1 I4 in line 4 cylinder water cooled petrol. Displacement: 3,285 litres. Power: 50hp @2800 rpm.

Max speed: 70/43.5mph. Fuel tank capacity: 40 litres/ 8.7 gallons. Fuel consumption: 18.5 ltr -100km/ 4.6 gall - 62 miles.

The engine had the ability to operate with low grade octane fuel

TRANSMISSION: Unsynchronised manual mechanical gearbox. 4 forward gears, one reverse gear.

DIMENSIONS: Wheelbase: 3340mm/ 131.49in.

Length: 5335mm/ 210.39in.

Width: 2040mm/ 80.31in.

Height:1970/ 77.55in.

Kerb weight: 1810kg/3990 lb.

Carrying capacity: 1500kg/1.4763 UK Long Ton.

Personnel: Cab x2, Rear x 16 persons seated.

The first GAZ-AA's were made according to specifications of the original Ford, however Soviet designers found it necessary to make some changes including strengthening the clutch, steering gear, install an air filter, other components and simplification of the model. Incidentally, the GAZ-AA had no fuel pump. The tank was located in front of the wind screen above the carburettor and fuel was fed into it by gravity. The vehicle also shared many components with the GAZ 67 light utility vehicle, including the engine. The vehicle was produced in many guises for civil use i.e. medical, fire, police, buses as well as commercial transport etc.

It was also adopted by the Red Army and 151,000 were in use at the start of the Great Patriotic War. The vehicle delivered the base for countless variations, for troop and cargo transport, ambulances, buses, command, signal, fuel bowsers, artillery towing, mobile workshop, vehicle mounted anti-aircraft gun and quadruple machine gun use, as well as the 3-axle GAZ-AAA and the GAZ-60 halftrack variants.

The term GAZ MM was the designation for wartime vehicles produced from early 1942 on wards. It incorporated the strengthened engine introduced in 1938, increasing output from 42 to 50 hp. Modifications varied, including a canvas or leatherette roof, plain welded steel fenders replacing the curved pressed ones, no front brakes, no front bumper bar and sometimes no doors, and only one headlight From mid-1942 trucks were also produced with wooden doors with sliding part windows. In 1944 the hinged drop side panels were abolished leaving the tailgate hinged only.

It was nicknamed the " Polutorka", which referred to the vehicles payload capacity of one and a half tons.(Transliteration in Russian, "poltora" means one and a half).

The example pictured was made in 1940 and is fitted with the pre 1941 cab with pressed steel doors. Apparently it went back to the factory at some point after being damaged in the field to have a plate welded on the chassis (combat damage?).

At the same time the curved pressed steel fenders may have also been changed for the flat welded steel fenders.

It was imported into the UK in August 2015 from Slovakia.

Specifications.

LAY OUT: Front engine rear wheel drive vehicle.

ENGINE: GAZ-M1 I4 in line 4 cylinder water cooled petrol. Displacement: 3,285 litres. Power: 50hp @2800 rpm.

Max speed: 70/43.5mph. Fuel tank capacity: 40 litres/ 8.7 gallons. Fuel consumption: 18.5 ltr -100km/ 4.6 gall - 62 miles.

The engine had the ability to operate with low grade octane fuel

TRANSMISSION: Unsynchronised manual mechanical gearbox. 4 forward gears, one reverse gear.

DIMENSIONS: Wheelbase: 3340mm/ 131.49in.

Length: 5335mm/ 210.39in.

Width: 2040mm/ 80.31in.

Height:1970/ 77.55in.

Kerb weight: 1810kg/3990 lb.

Carrying capacity: 1500kg/1.4763 UK Long Ton.

Personnel: Cab x2, Rear x 16 persons seated.

M72 Soviet military motorcycle combination.

The Soviet built M-72 was a replacement for the pre war TIZ-AM-600 and PMX-A-750 motorcycles used by the Red Army, which were considered out dated designs. The replacement chosen was the based on the 1938 German BMW R 71. In 1939 the Molotov-Ribbentrop Pact enabled the transfer of technology between Germany and the Soviet Union. As part of the pact, manufacturing plans were passed to the Soviets for the BMW R-71. Production was at three factories located in Moscow(MMZ), Leningrad(LMZ) and Kharkov(KMZ).Only the Moscow factory produced complete motorcycles prior to the German invasion in June 1941.

The Moscow factory was subsequently moved east to the town of Irbit in Western Siberia and renamed IMZ. The Kharkov and Leningrad factories were relocated to Gorki near the GAZ car and truck plant and renamed GMZ. During the war, motorcycles were produced at both IMZ and GMZ. All sidecars for both the M-72 and Lend Lease bikes were produced at Gorki.

M-72 motorcycles were predominantly produced with a sidecar attached, although some solo motorcycles were made for dispatch, escort roles and reconnaissance units. M-72 were produced at IMZ in Irbit from 1942 until 1955. A subsequent model, the M-72M was produced from 1955 until 1960. The machine was manufactured only for army use until the early 1950's, thereafter it became available to the civilian market.

The excellent example in the images (Dnepr K750) was made in the 1950's and was imported to the UK in the early 1960's. It bears it's original Soviet military registration number and is fitted with M1944 DPM light machine gun on the sidecar mount. It portrays a vehicle of the 76th Motorcycle Infantry Battalion, which was assigned to the 4th Guards Tank Corps on the 1st May 1943 and remained with the Corps until the end of the war

Length: 2420mm, width: 1600mm, height: 980mm. Weight (fuelled): 225 kg (solo), 350 kg (with sidecar).

Three personnel could be carried on the combination plus a load of 100kg.

Wheelbase: 1400mm.

Road clearance: 135mm.

Engine: 746cc, 26hp/4900rpm, 2-cylinder air cooled 4-stroke SV with horizontal opposed cylinders.

Maximum speed (with sidecar): 85 km/h except M-72N 90 km/h and M-72K 120 km/h.

Bore/Stroke: 78 mm.

Clutch: dry twin plates (very early models - one plate).

Gearbox: 4 speed with hand and foot shift.

Ratios: I - 3,60, II - 2,28, III - 1,7, IV - 1,30

Differential ratio: 3,86, 4,62 from 1944 onward.

Shaft drive connecting rear wheel to sidecar wheel.

Front suspension: telescopic type with hydraulic shock absorbers except on M-72N leading link type.

Rear suspension: telescopic type.

Frame: tube type Cardan.

Mechanical drum brakes on front and rear wheels.

Tyres: 3.75-19 inches, wheels are interchangeable.

Fuel tank capacity: 22 litres. Fuel consumption (with sidecar): 7 L/100km under 50-60 km/h.

Engine oil capacity: 2 litres.

Oil consumption: 0,25 L/100 km.

Transmission oil capacity: 0,8 litres.

Differential oil capacity: 0,175 litres.

The Moscow factory was subsequently moved east to the town of Irbit in Western Siberia and renamed IMZ. The Kharkov and Leningrad factories were relocated to Gorki near the GAZ car and truck plant and renamed GMZ. During the war, motorcycles were produced at both IMZ and GMZ. All sidecars for both the M-72 and Lend Lease bikes were produced at Gorki.

M-72 motorcycles were predominantly produced with a sidecar attached, although some solo motorcycles were made for dispatch, escort roles and reconnaissance units. M-72 were produced at IMZ in Irbit from 1942 until 1955. A subsequent model, the M-72M was produced from 1955 until 1960. The machine was manufactured only for army use until the early 1950's, thereafter it became available to the civilian market.

The excellent example in the images (Dnepr K750) was made in the 1950's and was imported to the UK in the early 1960's. It bears it's original Soviet military registration number and is fitted with M1944 DPM light machine gun on the sidecar mount. It portrays a vehicle of the 76th Motorcycle Infantry Battalion, which was assigned to the 4th Guards Tank Corps on the 1st May 1943 and remained with the Corps until the end of the war

Length: 2420mm, width: 1600mm, height: 980mm. Weight (fuelled): 225 kg (solo), 350 kg (with sidecar).

Three personnel could be carried on the combination plus a load of 100kg.

Wheelbase: 1400mm.

Road clearance: 135mm.

Engine: 746cc, 26hp/4900rpm, 2-cylinder air cooled 4-stroke SV with horizontal opposed cylinders.

Maximum speed (with sidecar): 85 km/h except M-72N 90 km/h and M-72K 120 km/h.

Bore/Stroke: 78 mm.

Clutch: dry twin plates (very early models - one plate).

Gearbox: 4 speed with hand and foot shift.

Ratios: I - 3,60, II - 2,28, III - 1,7, IV - 1,30

Differential ratio: 3,86, 4,62 from 1944 onward.

Shaft drive connecting rear wheel to sidecar wheel.

Front suspension: telescopic type with hydraulic shock absorbers except on M-72N leading link type.

Rear suspension: telescopic type.

Frame: tube type Cardan.

Mechanical drum brakes on front and rear wheels.

Tyres: 3.75-19 inches, wheels are interchangeable.

Fuel tank capacity: 22 litres. Fuel consumption (with sidecar): 7 L/100km under 50-60 km/h.

Engine oil capacity: 2 litres.

Oil consumption: 0,25 L/100 km.

Transmission oil capacity: 0,8 litres.

Differential oil capacity: 0,175 litres.

The 76th Motorcycle "Dembitsky" Red Banner, Order of Alexander Nevsky Battalion.

The Battalion was formed in Noginsk, Moscow District in November 1942 and was to be combat ready by January 30th 1943. On 1st February the Battalion was assigned to the 7th Mechanised Corps Reserve. The Battalion was assigned to the 4th Guards Tank Corps on the 1st May 1943 and remained with the Corps until the end of the war. During the war it served within the Active Army from 09/07/1943 to 03/09/1943 and from 07/12/1943 to 11/05/1945.The primary role of the motorcycle battalion was reconnaissance and to provide flank protection support to the advancing forward elements of the Tank Corps.

On 7th September 1944, for distinguished combat service the battalion was awarded the honorific title " Dembitsky" for participation in the capture of the city of Debica in south eastern Poland. On the 19th February 1945, for exemplary service the battalion was awarded the Order of the Red Banner for the breach of German defense to the west of Sandomierz.

On the 28th May 1945 for the exemplary fulfillment of the command tasks in battles for the breakthrough of the defence of the Germans on the Neisse River and for the seizure of the towns of Cottbus, Lubben, Zossen, Beelitz, Luckenwalde, Troyenbritsen, Tsana, Marienfelde, Trebbin, Rangsdorf, Didersdorf and Celts the battalion was awarded the Order of Alexander Nevsky.

On 7th September 1944, for distinguished combat service the battalion was awarded the honorific title " Dembitsky" for participation in the capture of the city of Debica in south eastern Poland. On the 19th February 1945, for exemplary service the battalion was awarded the Order of the Red Banner for the breach of German defense to the west of Sandomierz.

On the 28th May 1945 for the exemplary fulfillment of the command tasks in battles for the breakthrough of the defence of the Germans on the Neisse River and for the seizure of the towns of Cottbus, Lubben, Zossen, Beelitz, Luckenwalde, Troyenbritsen, Tsana, Marienfelde, Trebbin, Rangsdorf, Didersdorf and Celts the battalion was awarded the Order of Alexander Nevsky.